About - In-situ Galvanising Metallic Paint

Main menu:

About

COOL GALV is...

1. Most Advanced IN-SITU film galvanizing system which give 96% zinc in dry film for Active Cathodic Protection comparable to Hot-Dipped galvanising(HDG)

2. Nanotechnology and special resin to stabilise and control the depletion of the ultra fine atomized zinc dust .

3. One component metallic coating with no limitation on pot life and shelf life.

4. Easy to replenish/recharge the old Cool Galv by blending into homogeneous single paint film.

5. Easy to repair and replenish the aged/damaged hot-dip galvanizing or thermal spray structures.

6. Will not crack, come loose or peel off like IOZ or EPZR

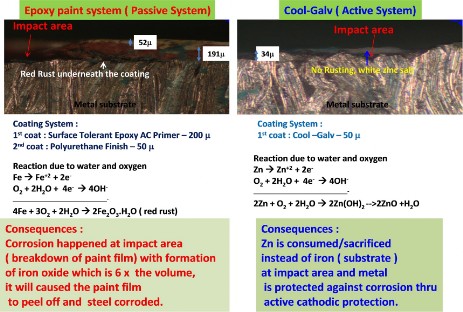

Active Cathodic Protection Vs Passive Barrier Protection :

Cool Galv provide active cathodic protection and act as sacrificial anode to protect the underneath metal substrate, once the atomised zinc particle is oxidised, it further fortified the paint film for barrier protection. The metal is still protected from corrosion even a slight breakdown of paint film.

Whereas conventional epoxy primer and protective coating system, it only provide passive barrier protection by blocking the water/moisture and oxygen from in contact with the metal substrate, once there is breakdown of the paint film due to mechanical damage or natural deterioration of the polymer, water and oxygen will seep through and corrosion will occured, resulting the break down the barrier coating.

The Advantages of Cool Galv

SIMPLE – Ease of Application

1-Pack product with no shelf life and pot life.

Easy to Apply by brush, roller, spray or dipping

Minimum Surface Preparation of Clean Sa 2.5, Sa2.0 , St 3 or St 2

Can Apply on Damp surface after High Pressure water-jet cleaning

As Top Coat by itself or Duplex system with PU, epoxy , acrylic

Easy to Carry-around & Use for new building or repair of Hot-dipped galvanising, thermal-spray, bare & coated steel structures.

SUPERIOR – Long Term Protection

Life Time Protection like Hot-dipped Galvanizing (HDG)

Active Cathodic Protection like HDG but apply as a paint.

Comply to ISO 12944-6 C5M / C5I High ( Tested by TUV SUD PSB)

Require 80-160m in 1-2coats for protection expectancy up to 15 yrs

Good mechanical properties and paint film will not crack or peel off

SAVE – Cost Effective and Environmental Friendly

Non-toxic -does not contain Xylene, Ethyl benzene or MEK.

Cheap & Effective as alternative to Hot-Dipped Galvanising (HDG)

More Economical than conventional 3-coats system

Extend Service Life of HDG and metallising structures by replenish and restore the Active Cathodic Protection.

Reduce Maintenance- extend maintenance cycle with minimum secondary surface preparation.